1, 46019

Business Type:

Business Range:

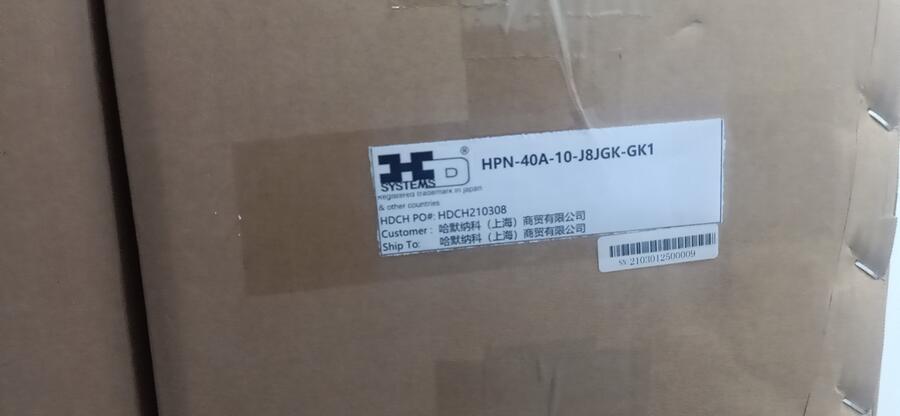

Harmonic Drive,Planetary reducer,Servo motor driver,

Management System Certification:

Terms of Payment:

OEM/ODM Availability:

Industrial cloud member

13 years

Audited Supplier