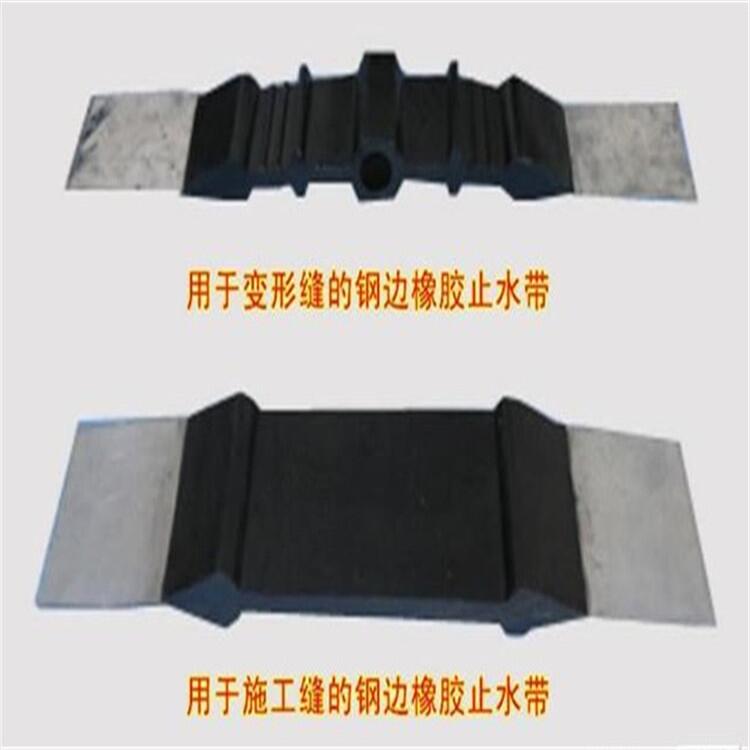

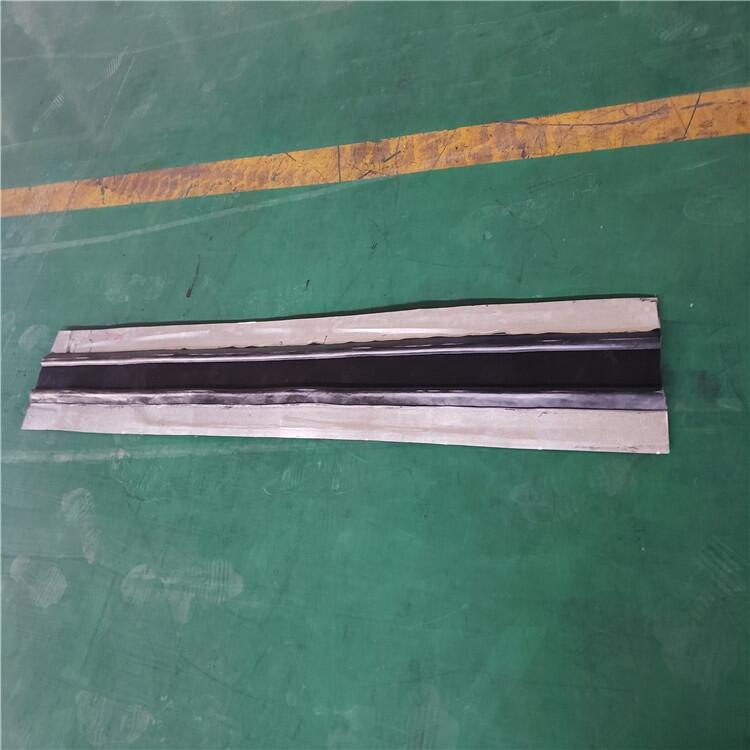

The cross joint of steel edge rubber water stop belt is used at the junction of horizontal construction joint and vertical construction joint, and the straight section is used at horizontal or vertical construction joint. The two joints are joined together by hot fusion, and finally the rubber waterproof of construction joint is bed. Medium-buried steel-edge rubber water-stop connection bbbbbb: before the buried steel-edge rubber water-stop is welded, the weld joint, welding die, raw film, rubber and steel-sheet connector, polishing tool, clean cloth, etc. should be prepared.

中埋式钢边橡胶止水带熔接方法如下:

Medium-buried steel-edge rubber water stop is welded as follows:

(1)将钢边橡胶止水带两头,即直线段与十字接头连接端各大约100mm处的橡胶割掉,用工具,如砂轮将钢边打磨光滑。

(1) Cut off the rubber at the two ends of the rubber water stop tape on the steel edge, i.e. the connecting end of the straight line segment and the cross joint, which is about 100 mm large, and polish the steel edge smoothly with tools such as grinding wheels.

(2)将钢边橡胶止水带需要熔接的两端头搭接处中间留下长30~40mm的空间用于接头熔接、干净生胶片的连接。如果生胶片占有灰尘须用干净布擦干净灰尘或用打磨机将生胶片表面打磨干净后才能使用。

(2) Leave a space of 30-40 mm in the middle of the overlap between the two ends of the steel-edged rubber water stop belt which need to be welded for the joint welding and the connection of clean raw film. If the raw film occupies dust, it must be cleaned with a clean cloth or polished with a grinder to clean the surface of the raw film before it can be used.

(3)在已打磨光滑的钢边两面涂刷橡胶与金属粘结剂。

(3) Rubber and bl binders are applied on both sides of polished smooth steel.

(4)在加工打磨钢板橡胶止水带连接端头的同时预热橡胶止水带的熔接模具好,预热时间按电热丝的发热功率约在30分钟。目的是将模具温度控制在140~150℃度之间。当温度计显示模具温度已到140~150℃即可进行后续步骤。

(4) The welding die of the preheated rubber water stop is good while grinding the connection end of the steel plate rubber water stop. The preheating time is about 30 minutes according to the heating power of the electric heater wire. The aim is to control the temperature of the die between 140 and 150 degrees C. When the thermometer shows that the temperature of the die has reached 140-150 C, the follow-up steps can be carried out.

(5)把需要熔接钢边橡胶止水带两端头按步骤2搭接放入橡胶熔接模具底模的中间,连接处放满生胶片。

(5) Place the two ends of the rubber sealing tape with steel edge to be welded in the middle of the bottom die of the rubber welding die according to step 2, and fill the connection with raw film.

(6)按模具的对中孔洞,轻轻放置熔接模具的顶模。在安放模具顶模的过程中要避免生胶片和熔接端头的跑位,如果过程中钢边橡胶止水带需熔接的两端头跑位,需重复此步骤,确保熔接两端头的正确位置。

(6) Place the top die of the welding die gently according to the middle hole of the die. In the process of placing the top die of the die, the running of raw film and fusion end should be avoided. If the two ends of the steel-edged rubber water stop need to be welded in the process, this step should be repeated to ensure the correct bbbbbbbb of the fusion ends.

(7)用千斤顶将安放好的顶模具加压。此步骤注意的是:第一次千斤顶加压压力不要过大大,加压至模具顶模和底模之间距离在2cm左右。待熔接钢边橡胶止水带的生胶片硫化一段时间,约5~10分钟后再进行千斤顶的二次加压。

(7) Pressure the mounted jacking die with a jack. This step is to note that the pressure of the first jack should not be too large, and the distance between the pressure and the top and bottom dies of the die should be about 2 cm. The raw rubber sheet of the welded steel edge rubber water stop tape is vulcanized for a period of time, and the second pressure of the jack is applied after about 5 to 10 minutes.

(8)千斤顶二次加压是将模具缝隙加压至设计钢边橡胶止水带断面。加压后,保持模具温度在140~150℃之间,时间约20~30分钟即可开模。

(8) The second pressurization of the jack is to press the die gap to the section of the rubber water stop at the design steel edge. After pressing, the mould temperature is kept between 140 and 150 degrees C, and the mould can be opened in about 20 to 30 minutes.

(9)开模检查。如检查发现生胶片熔合不饱满,存在缺胶、开裂、分层等现象需返回至步骤1重新开始钢板橡胶止水带的端头热熔接。如检查发现橡胶止水带接头处熔合饱满,不脱胶,可以进行下一步骤。

(10)将已熔接好的钢边止水带的钢边连接处用钉子或钢丝连接好,或将此接头连接处的钢边焊接牢固。

(10) Connect the steel edge joints of the welded steel edge water stop strip with nails or steel wires, or weld the steel edges of the joints firmly.

- 西门子全新原装手操器AZL52.00B1 特价供应未开封

- 西门子原装进口伺服电机 SQM48.497B9

- 全新SICK编码器AFM60A-BDNB018X12 绝对值

- SICK色标传感器德国KTS-WB9114115AZZZZZZ11078126

- LFP0530-G5NMCS37 SICK全新原装镜反射传感器原装正品

- 6ES7461-1BA007AA0原装正品

- 6ES7455-1VS00-0AE0现货

- 6ES7414-2XG01-0AB0新品热卖

- 6ES7468-1CC50-0AA0原装正品

- 6ES7414-4HM14-0AB0量大从优

- 6ES7405-0KR02-0AA0模块

- 6ES7408-1TX00-6XA0产地

- 三菱代理商,三菱L系列PLC,LPLC

- 6ES7408-1TA00-0XA0模块

- 6ES7408-1TA00-0XA0质保一年