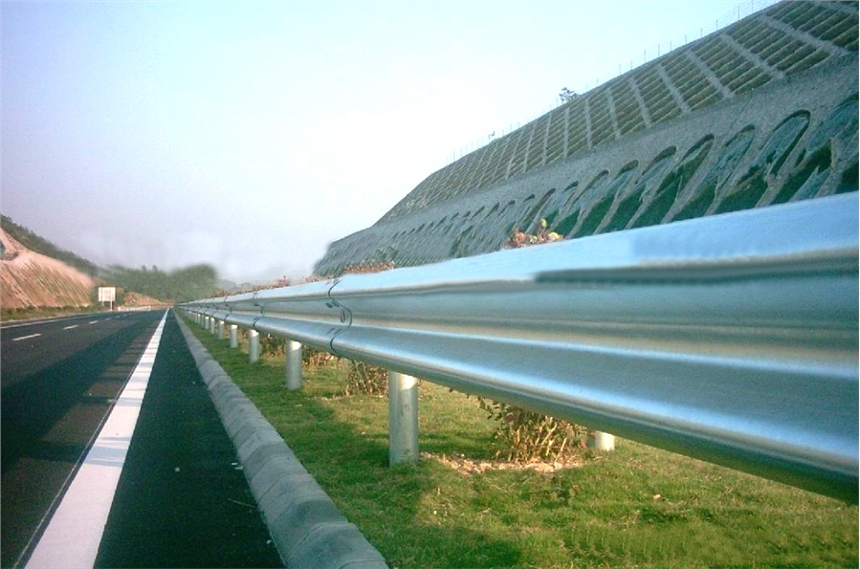

(1)波形梁护栏板、立柱、防阻块、横隔梁、端头、螺栓、螺母等构件应合适《高速公路波形梁钢护栏》(JT/T281—1995)及《公路三波形梁钢护栏》(JT/T457—2001)产物尺度的划定。出产厂方在供给产物时,应同时提交产物质量及格证书。(1)wavebbeamplate,averticalcolumn,anantiblock,crossbeamandanend,bolts,nutsandothercomponentsseparatedshouldconbtotherequirementsofthehighwayguardrail"(JT/T281-1995)andtheroadthreewavebeamsteelguardrail"(JT/T457--2001)standardproductsof.Themanufacturersinprovidingproducts,productqualitycertificateshouldbebtedatthesametime.(2)波形梁板、立柱、防阻块、端头、托架等部件应合适《碳素布局钢》(GB/T700—1988)的Q235商标钢的要求。

(2)wavebeamplate,column,block,end,bracketandotherpartsshouldbeinaccordancewiththe"carbonstructuralsteel"(GB/T700-1988)oftheQ235gradesofsteelrequirements.(3)毗连螺栓、螺母、垫圈、横梁垫片等部件应合适《碳素布局钢》(GB/T700—1988)的要求,其抗拉强度不得小于375MPa和400MPa(别离合用于JT/T281—1995和JT/T457—2001)。(3)connectingbolts,nuts,washers,beamgasketcomponentsshouldcomplywiththe"carbonstructuralsteel"(GB/T700-1988)requirements,thetensilestrengthshallnotbelessthan375MPaand400MPa(wereappliedtoJT/T281-1995andJT/T457,2001).(4)高强度拼接螺栓毗连副应合适《低合金高强度布局钢》(GB/T1591-1994)、《优质碳素布局钢》(GB/T699-1999)或《合金布局钢》(GB/T3077-1999)的要求。

公称直径16mm、8.8S级抗拉荷载不得小于133kN。(4)highstrengthboltedspliceconnectiondeputyshallcomplywiththerequirementsofthelowalloyhighstrengthstructuralsteel"GB/T1591-1994,thehighqualitycarbonstructuralsteel"GB/T699-1999orthealloystructuresteel,GB/T3077-1999,nominaldiameterof16mm,8.8stensileloadshallnotbelessthan133kN.(5)为包管产物质量。

对波形梁护栏各部件的外不雅、尺寸、防腐处置进行抽样查抄。不不异的部件各以200件一批为取样单元,别离掏出一片护栏板、一个端头、一根立柱、一块托架进行查抄,若是受检的构件不合适要求,另取两件查验;若是这两件中仍有一件不合适要求,则以此为样品的整批产物应被拒收,一切费用由承包人自付。(5)toensurethequalityofproducts,theappearance,sizeandcorrosionresistanceofvariouspartsoftheguardrailsweresampledandchecked.Differentcomponentsto200piecesofanumberofsamplingunit,respectively,removedapieceofguardrailplate,ahead,anuprightt,abracketareexamined,ifbyinspectionofthecomponentdoesnotmeettherequirements,takeanothertest;ifthisisstilladoesnotmeettherequirements,thetosampletheentirebatchofproductsshouldberejected,allexpensesbythecontractorpays.(6)护栏板、端头梁、立柱的长度和宽度标的目的不许可焊接。

构件不该呈现裂痕。(6)thelengthandboftherail,theendofthebeamandthecolumnarenotallowedtobewelded,andthemembersshouldnotcrack.(7)高强度螺栓应抽样进行楔负载拉力试验,断裂应发生在螺纹部门或螺纹与杆部交代处;如不克不及做楔负载拉力试验,则应做芯部硬度试验,芯部硬度值为洛氏HRC34~40。螺母应抽样进行包管荷载和硬度试验。(7)ofhighstrengthboltsshouldbesampledtowedgeloadtensiletest,fractureoccurredatthethreadedportionorthreadandrodjunction;ifnotwedgetensileloadtest,youshoulddocorehardnesstest,hardnessofthecorbuesofRockwellHRC34~40.Thenutshallbesampledtoensuretheloadandhardnesstest.(8)每批高强螺栓都应有出厂及格证。

螺栓毗连副扭矩应附有扭矩系数的平均值、尺度误差的试验数据和扭矩系数测试时的情况温度等手艺资料。(8)eachbatchofhighstrengthboltsshouldhavethefactorycertificate,theboltconnectionvicetorqueshouldbeaccompaniedbythetorquecoefficientoftheaveragbue,standarddeviationofthetestdataandtorquecoefficienttestenvironmenttemperatureandothertechnicalinbation.(9)波形梁护栏、勾当式钢护栏及螺栓、螺母、垫圈、垫片等所有部件均应按《高速公路交通工程钢构件防腐手艺前提》(GB/T)的划定采用热浸镀锌(铝)进行金属概况处置;

热浸镀锌应采用《锌锭》(GB/T470—1997)中所划定的特一号锌锭或一号锌锭,镀锌构件锌层质量应合适表602-1的划定。热浸镀铝应采用《重熔用铝锭》(GB/T1196-1993)中所划定的特一级、特二级、一级铝锭,镀铝构件铝层质量应合适表602-2的划定。(9)W-beamguardrail,activitytypesteelguardrailandbolts,nuts,washers,gaskets,etc.allthepartsshallbeinaccordancewiththeprovisionsofthehighwaytrafficengineeringsteelstructureanticorrosiontechnicalconditions"GB/Tbyhotdipgalvanized(AL)blsurfacetreatment;hotdipgalvanizingshouldadoptthe"zinc"(GB/T470-1997stipulatedthespecialNo.azincingotsor1zincingots,componentgalvanizedzinclayerqualityshallconbtospecifiedintable602-1.Hotdipaluminumshouldadopttheremeltingwithaluminumingot"(GB/T1196-1993)requiredaspecial,specialsecondaryandprimaryaluminumingot,aluminumaluminumcomponentlayerqualityshallconbtotherequirementsintable602-2.高强度螺栓进行热浸镀锌处置后。

对高强度螺栓毗连件概况要涂黄油,并进行磷化润滑处置,在出厂时应密封包装,以防运输、保留时代生锈或弄脏。Hotdipgalvanizedhighstrengthbolts,ofhighstrengthboltconnectionsurfaceshouldbecoatedwithbutter,andphosphatizinglubrication,inthefactoryshouldbesealedpackaging,topreventtransportation,preservationperiodofrustordirty.(10)镀锌构件的锌层应平均,试样经溶液浸蚀5次不变红,并合适《高速公路波形梁钢护栏》(JT/T281-1995)附录B的划定;

镀锌构件的锌层应与基底金属连系安稳,经捶击试验镀锌层不剥离、不凸起,并合适《高速公路波形梁钢护栏》(JT/T281-1995)附录C的划定。(10)componentgalvanizedzinclayershouldbeunibsamplebyetchingofthecoppersulphatesolution,5timesthesamered,andinaccordancewiththeprovisionsofthehighwayguardrail,JT/T281-1995AppendixB;componentgalvanizedzinclayershouldbeandbaseblisfirmlycombinedbyhammeringtestgalvanizedlayernotpeeling,notraised,andinaccordancewiththeprovisionsofthehighwayguardrail,JT/T281-1995AppendixC.The(11)镀铝构件的铝层应平均。

- 全新伺服电机ILM1003P11A0000说明书

- 施耐德驱动器LMC402CCB10000现货特价

- 供应伺服电机BMH1403P01A2A现货特价

- 供应伺服电机ILM0701P32A0000使用方法

- 供应伺服电机BMH1403P16F1A现货低价

- 施耐德驱动器LMC400CAA10000图片

- 供应伺服电机ILM0702P31A0000特点

- 伺服驱动器LMC802CBD10000图片

- 伺服驱动器LMC402CCA10000简介

- 施耐德伺服电机ILM0702P22F0000说明书

- 伺服驱动器LXM23CU30M3X市场价格

- 供应伺服电机BMH1403P17A1A技术参数

- 伺服驱动器LMC802CBB10000现货供应

- 施耐德伺服电机BMH1403P06A2A优势库存

- 供应伺服电机ILM0701P31A0000技术参数