产品简介

详细说明

The production process of the fiber cement board production line mainly includes copying b, slurry flow b, molding b and vacuum extrusion b. The most commonly used bs are the stripping b and the slurry flow b. The stripping process, also known as the "rotary screen stripping b", originates from the manufacturing b of fiber cement board invented by Austrian people on the basis of the papermaking process. After more than a hundred years of discussion, research and exploration in different countries, scientists have constantly innovated and improved this process. The stripping b has become one of the production processes with sophisticated technology and wide application in the product industry.

In the process of taking and making boards, fibers are mostly arranged in two-dimensional plane orientation, and the arrangement direction is mainly along the circular mesh, which is consistent with the direction of the main stress of the board, and can be adjusted by other means of assistance to produce different products.

In the process of taking and making boards, fibers are mostly arranged in two-dimensional plane orientation, and the arrangement direction is mainly along the circular mesh, which is consistent with the direction of the main stress of the board, and can be adjusted by other means of assistance to produce different products.

The material layer made by the copying process is obtained from multiple cages, normally 3-6 cages. Each material layer is composed of small material layers obtained from multiple cages. The material layer is flat, the pressure is unib, and the internal structure of the slab is fine.

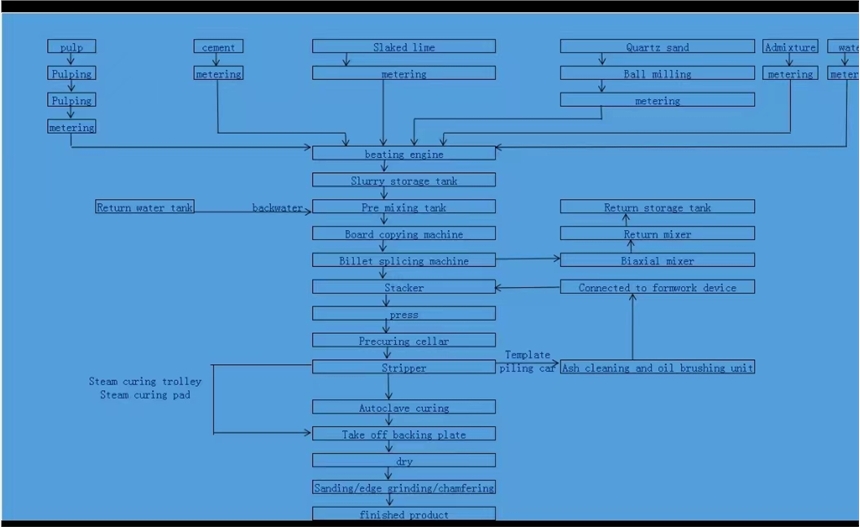

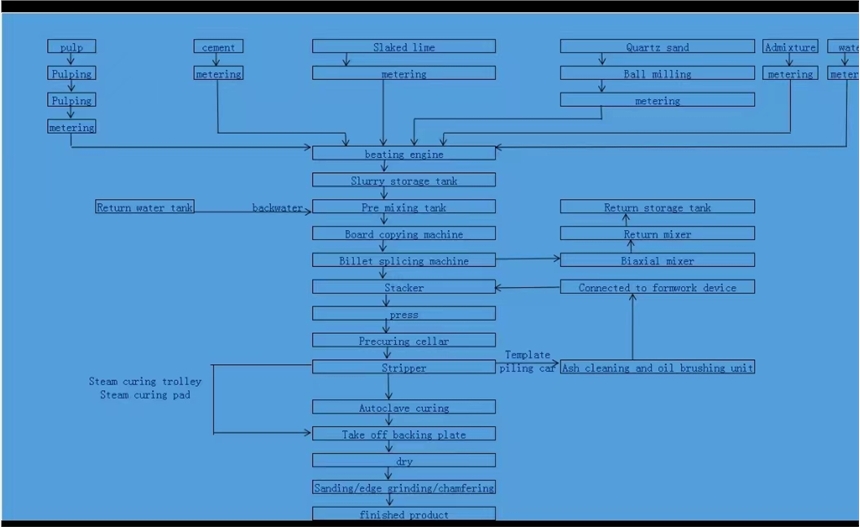

以下是抄取法工艺详细流程图:

在线询盘/留言

免责声明:以上所展示的信息由企业自行提供,内容的真实性、准确性和合法性由发布企业负责,本网对此不承担任何保证责任。我们原则 上建议您选择本网高级会员或VIP会员。

企业信息

最新供应

- 美国AB变频器22B-D012N204特惠

- 罗克韦尔变频器20BC260A0ANNANC0技术参数

- 美国AB变频器22B-D010H204设备型号

- 罗克韦尔变频器20BC105A0AYNACC1现货低价

- 美国AB变频器22F-A8P0N103特点

- 罗克韦尔变频器20AC037C0AYNANC0优惠

- 罗克韦尔变频器20BC105A0AYNANA0技术参数

- 罗克韦尔变频器20AC030A3NYNANC0厂家直销

- 罗克韦尔变频器22B-D4P0N104设备型号

- REXROTH BOSCH R900433346

- 广西台达DVP14SS211R可编程控制器14点主机销售代理

- 美国AB变频器20BC260A3ANNADC0现货特价

- Parker VM125A10VM

- 罗克韦尔变频器22F-A4P2N113说明书

- Rexroth DR-10-4-52/315XY

推荐供应