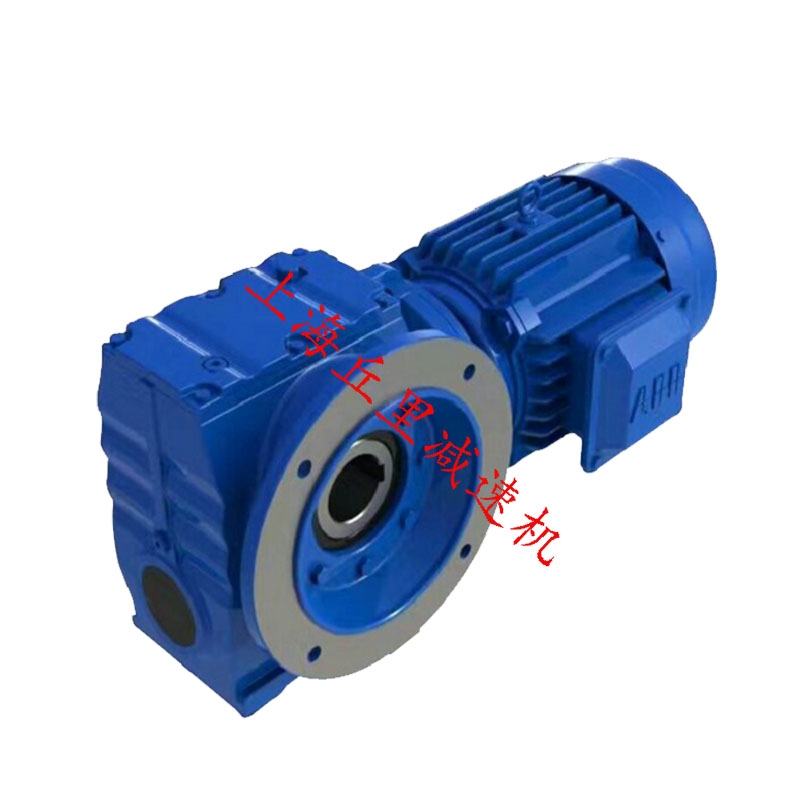

K系列螺旋锥齿轮减速机产品概述:

k系列锥齿轮减速机是本公司技术人员根据在SEW产品架构模型并结合我国工业

领域实际使用环境和机械性能要求进行设计研发的。本系列产品通用性强,使

用维护方便,维护成本低,特别是生产线,只需要备用内部几个传动件即可保

证整线正常生产的维修保养。由于采用单元结构模块化设计原理,大量减少了

零部件种类和库存量,也大大的缩短了交货周期。传动效率高、耗能低、性能

优越。带筋的高刚性铸铁箱体;硬齿面齿轮采用优质合金钢,表面经渗碳淬火

硬化处理,磨齿精加工,传动平稳、噪声低、承载能力大,温升低、寿命长。

此外本系列产品采用新型密封装置,保护性能好,对环境适应性强,可在有腐

蚀,潮湿等恶劣环境中连续工作。K系列斜齿轮减速电机是模块组合体系的基础

上设计的新一代机电一体化产品,可分别与普通、制动、防爆、变频、伺服等

电机组合,可在立体空间六个方位任意安装。

结构形式:K-轴伸式、底脚安装;KA-轴装式联接;KF-轴伸式、法兰安装;

KAF-轴装式、法兰安装;D-表示轴输入。

部分斜 齿轮螺旋伞齿轮减速机斜齿轮减速机重载型减速机具体型号:

K37-Y0.18-4P-5.36-M1-180° ~ K37-Y3.0-4P-106.38-M1-180°;

K47-Y0.18-4P-5.81-M1-180° ~ K47-Y3.0-4P-131.87-M1-180°;

K57-Y0.18-4P-6.57-M1-180° ~ K57-Y5.5-4P-145.14-M1-180°;

K67-Y0.18-4P-7.14-M1-180° ~ K67-Y5.5-4P-144.79-M1-180°;

K77-Y0.37-4P-7.24-M1-180° ~ K77-Y11-4P-192.18-M1-180°;

K87-Y0.75-4P-7.19-M1-180° ~ K87-Y22-4P-197.37-M1-180°;

K97-Y1.1-4P-8.95-M1-180° ~ K97-Y30-4P-176.05-M1-180°;

K107-Y3-4P-8.74-M1-180° ~ K107-Y45-4P-141.46-M1-180°;

K127-Y7.5-4P-8.68-M1-180° ~ K127-Y90-4P-146.07-M1-180°;

K157-Y11-4P-12.65-M1-180° ~ K157-Y160-4P-150.41-M1-180°;

K167-Y11-4P-17.28-M1-180° ~ K167-Y200-4P-163.91-M1-180°;

K187-Y18.5-4P-17.27-M1-180° ~ K187-Y200-4P-180.78-M1-180°;

KA37-Y0.18-4P-5.36-M1-180° ~ KA37-Y3.0-4P-106.38-M1-180°;

KA47-Y0.18-4P-5.81-M1-180° ~ KA47-Y3.0-4P-131.87-M1-180°;

KA57-Y0.18-4P-6.57-M1-180° ~ KA57-Y5.5-4P-145.14-M1-180°;

KA67-Y0.18-4P-7.14-M1-180° ~ KA67-Y5.5-4P-144.79-M1-180°;

KA77-Y0.37-4P-7.24-M1-180° ~ KA77-Y11-4P-192.18-M1-180°;

KA87-Y0.75-4P-7.19-M1-180° ~ KA87-Y22-4P-197.37-M1-180°;

KA97-Y1.1-4P-8.95-M1-180° ~ KA97-Y30-4P-176.05-M1-180°;

KA107-Y3-4P-8.74-M1-180° ~ KA107-Y45-4P-141.46-M1-180°;

KA127-Y7.5-4P-8.68-M1-180° ~ KA127-Y90-4P-146.07-M1-180°;

KA157-Y11-4P-12.65-M1-180° ~ KA157-Y160-4P-150.41-M1-180°;

KA167-Y11-4P-17.28-M1-180° ~ KA167-Y200-4P-163.91-M1-180°;

KA187-Y18.5-4P-17.27-M1-180° ~ KA187-Y200-4P-180.78-M1-180°;

KF37-Y0.18-4P-5.36-M1-180° ~ KF37-Y3.0-4P-106.38-M1-180°;

KF47-Y0.18-4P-5.81-M1-180° ~ KF47-Y3.0-4P-131.87-M1-180°;

KF57-Y0.18-4P-6.57-M1-180° ~ KF57-Y5.5-4P-145.14-M1-180°;

KF67-Y0.18-4P-7.14-M1-180° ~ KF67-Y5.5-4P-144.79-M1-180°;

KF77-Y0.37-4P-7.24-M1-180° ~ KF77-Y11-4P-192.18-M1-180°;

KF87-Y0.75-4P-7.19-M1-180° ~ KF87-Y22-4P-197.37-M1-180°;

KF97-Y1.1-4P-8.95-M1-180° ~ KF97-Y30-4P-176.05-M1-180°;

KF107-Y3-4P-8.74-M1-180° ~ KF107-Y45-4P-141.46-M1-180°;

KF127-Y7.5-4P-8.68-M1-180° ~ KF127-Y90-4P-146.07-M1-180°;

KF157-Y11-4P-12.65-M1-180° ~ KF157-Y160-4P-150.41-M1-180°;

KF167-Y11-4P-17.28-M1-180° ~ KF167-Y200-4P-163.91-M1-180°;

KF187-Y18.5-4P-17.27-M1-180° ~ KF187-Y200-4P-180.78-M1-180°;

KAF37-Y0.18-4P-5.36-M1-180° ~ KAF37-Y3.0-4P-106.38-M1-180°;

KAF47-Y0.18-4P-5.81-M1-180° ~ KAF47-Y3.0-4P-131.87-M1-180°;

KAF57-Y0.18-4P-6.57-M1-180° ~ KAF57-Y5.5-4P-145.14-M1-180°;

KAF67-Y0.18-4P-7.14-M1-180° ~ KAF67-Y5.5-4P-144.79-M1-180°;

KAF77-Y0.37-4P-7.24-M1-180° ~ KAF77-Y11-4P-192.18-M1-180°;

KAF87-Y0.75-4P-7.19-M1-180° ~ KAF87-Y22-4P-197.37-M1-180°;

KAF97-Y1.1-4P-8.95-M1-180° ~ KAF97-Y30-4P-176.05-M1-180°;

KAF107-Y3-4P-8.74-M1-180° ~ KAF107-Y45-4P-141.46-M1-180°;

KAF127-Y7.5-4P-8.68-M1-180° ~ KAF127-Y90-4P-146.07-M1-180°;

KAF157-Y11-4P-12.65-M1-180° ~ KAF157-Y160-4P-150.41-M1-180°;

KAF167-Y11-4P-17.28-M1-180° ~ KAF167-Y200-4P-163.91-M1-180°;

KAF187-Y18.5-4P-17.27-M1-180° ~ KAF187-Y200-4P-180.78-M1-180°;

KAZ37-Y0.18-4P-5.36-M1-180° ~ KAZ37-Y3.0-4P-106.38-M1-180°;

KAZ47-Y0.18-4P-5.81-M1-180° ~ KAZ47-Y3.0-4P-131.87-M1-180°;

KAZ57-Y0.18-4P-6.57-M1-180° ~ KAZ57-Y5.5-4P-145.14-M1-180°;

KAZ67-Y0.18-4P-7.14-M1-180° ~ KAZ67-Y5.5-4P-144.79-M1-180°;

KAZ77-Y0.37-4P-7.24-M1-180° ~ KAZ77-Y11-4P-192.18-M1-180°;

KAZ87-Y0.75-4P-7.19-M1-180° ~ KAZ87-Y22-4P-197.37-M1-180°;

KAZ97-Y1.1-4P-8.95-M1-180° ~ KAZ97-Y30-4P-176.05-M1-180°;

KAZ107-Y3-4P-8.74-M1-180° ~ KAZ107-Y45-4P-141.46-M1-180°;

KAZ127-Y7.5-4P-8.68-M1-180° ~ KAZ127-Y90-4P-146.07-M1-180°;

KAZ157-Y11-4P-12.65-M1-180° ~ KAZ157-Y160-4P-150.41-M1-180°;

KAZ167-Y11-4P-17.28-M1-180° ~ KAZ167-Y200-4P-163.91-M1-180°;

KAZ187-Y18.5-4P-17.27-M1-180° ~ KAZ187-Y200-4P-180.78-M1-180°;

KAT37-Y0.18-4P-5.36-M1-180° ~ KAT37-Y3.0-4P-106.38-M1-180°;

KAT47-Y0.18-4P-5.81-M1-180° ~ KAT47-Y3.0-4P-131.87-M1-180°;

KAT57-Y0.18-4P-6.57-M1-180° ~ KAT57-Y5.5-4P-145.14-M1-180°;

KAT67-Y0.18-4P-7.14-M1-180° ~ KAT67-Y5.5-4P-144.79-M1-180°;

KAT77-Y0.37-4P-7.24-M1-180° ~ KAT77-Y11-4P-192.18-M1-180°;

KAT87-Y0.75-4P-7.19-M1-180° ~ KAT87-Y22-4P-197.37-M1-180°;

KAT97-Y1.1-4P-8.95-M1-180° ~ KAT97-Y30-4P-176.05-M1-180°;

KAT107-Y3-4P-8.74-M1-180° ~ KAT107-Y45-4P-141.46-M1-180°;

KAT127-Y7.5-4P-8.68-M1-180° ~ KAT127-Y90-4P-146.07-M1-180°;

KAT157-Y11-4P-12.65-M1-180° ~ KAT157-Y160-4P-150.41-M1-180°;

KAT167-Y11-4P-17.28-M1-180° ~ KAT167-Y200-4P-163.91-M1-180°;

KAT187-Y18.5-4P-17.27-M1-180° ~ KAT187-Y200-4P-180.78-M1-180°;

KAB37-Y0.18-4P-5.36-M1-180° ~ KAB37-Y3.0-4P-106.38-M1-180°;

KAB47-Y0.18-4P-5.81-M1-180° ~ KAB47-Y3.0-4P-131.87-M1-180°;

KAB57-Y0.18-4P-6.57-M1-180° ~ KAB57-Y5.5-4P-145.14-M1-180°;

KAB67-Y0.18-4P-7.14-M1-180° ~ KAB67-Y5.5-4P-144.79-M1-180°;

KAB77-Y0.37-4P-7.24-M1-180° ~ KAB77-Y11-4P-192.18-M1-180°;

KAB87-Y0.75-4P-7.19-M1-180° ~ KAB87-Y22-4P-197.37-M1-180°;

KAB97-Y1.1-4P-8.95-M1-180° ~ KAB97-Y30-4P-176.05-M1-180°;

KAB107-Y3-4P-8.74-M1-180° ~ KAB107-Y45-4P-141.46-M1-180°;

KAB127-Y7.5-4P-8.68-M1-180° ~ KAB127-Y90-4P-146.07-M1-180°;

KAB157-Y11-4P-12.65-M1-180° ~ KAB157-Y160-4P-150.41-M1-180°;

KAB167-Y11-4P-17.28-M1-180° ~ KAB167-Y200-4P-163.91-M1-180°;

KAB187-Y18.5-4P-17.27-M1-180° ~ KAB187-Y200-4P-180.78-M1-180°;

若有其他要求,可提供定做!

产品特性:

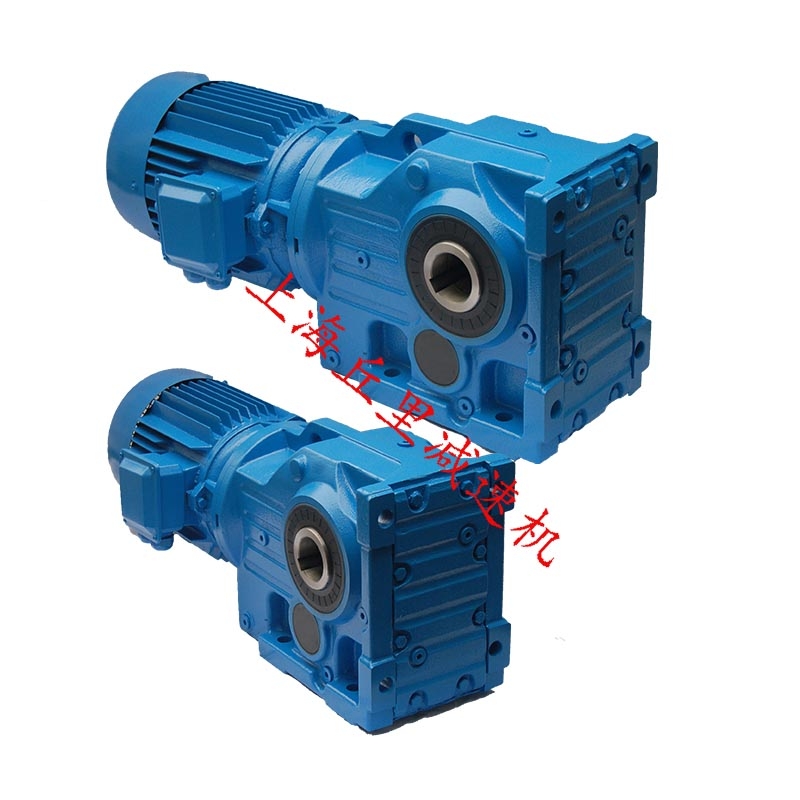

K系列斜齿轮螺旋伞齿轮减速机

K系列斜齿轮螺旋伞齿轮减速机是硬齿面R,F,S,K四大系列减速机中的K系列减速机。采用单元结构模块化设计原理,大大减少了零部件种类和库存量,也大大缩短了交货周期。带筋 的高刚性铸铁箱体、齿轮采用优质合金钢,磨齿精加工,传动平稳,噪声低,承载能力大,温升低,寿命长。

节省空间,可靠耐用,承受过载能力高,功率可达200KW,能耗低,性能优越,减速效率高达95%以上,

振动小,刚性铸铁箱体,齿轮表面经高频热处理,经过精密加工,构成了斜齿轮,伞齿轮

K系列斜齿轮螺旋伞齿轮减速机组成及应用

K系列斜齿轮螺旋伞齿轮减速机由两级或3级斜齿轮组成,与减速比有关,装在相同的箱体内。总共11个规格的斜齿轮螺旋伞齿轮减速机,转矩范围由3到22500NM。电机最大输出功 率为200KW。

K系列斜齿轮螺旋伞齿轮减速机的传动比范围从i=3.77到i=31434分级精细。可达到特别低的输出速度(带附加斜齿轮输入级的多级减速器)。

产品广泛应用于轻工、食品、啤酒饮料、化工、自动扶梯、自动化仓储设备、建筑、机械、钢铁冶金、造纸、人造板机械、汽车制造、烟草机械、水利、印刷包装、制药、纺织、

建材、物流、饲料机械、环境保护等领域。

型号示例:

KF67-Y3-4P-32.40-M1-0°

K:系列代号

F:轴伸法兰式安装

67:机型号

Y:三相交流异步电机

3:电机功率

4P:电机级数

32.40:传动比

M1:安装形式

0°:接线盒位置(0°-270°)

- 西门康IGBT功率模块SKM100GAL12T4

- Hilscher NS-5TX

- Hilscher NT 151-RE-RE/+ML

- AEG Hilscher PROFIBUS-DPM KPO 104-DPM

- ABB 3BSE020510R1 通信处理器模块

- HILSCHER CIF 50-IBS-OCP

- Hilscher AEG KPO-OIS Type: 9209012

- Hilscher PKV 9013051

- Hilscher CIFX50E-RE PC Card

- Hilscher Moby ASM 480 6GT2002-0JA0

- 赫思曼MSM40-T1T1T1T1TZ9HH9E99.9

- 赫思曼MSM40-T1T1T1T1SZ9HH9E99.9.

- 赫思曼MSM40-C1C1C1C1TZ9HH9E99.9

- 赫思曼MSM40-C1C1C1C1SZ9HH9E99.9

- 赫思曼MSM40-C1C1C1C1SZ9HH9E99.9.