WIKA 702.02.100 DELTA-comb

差压表 带集成工作压力表和微型开关

Differential pressure gauge with switch contacts

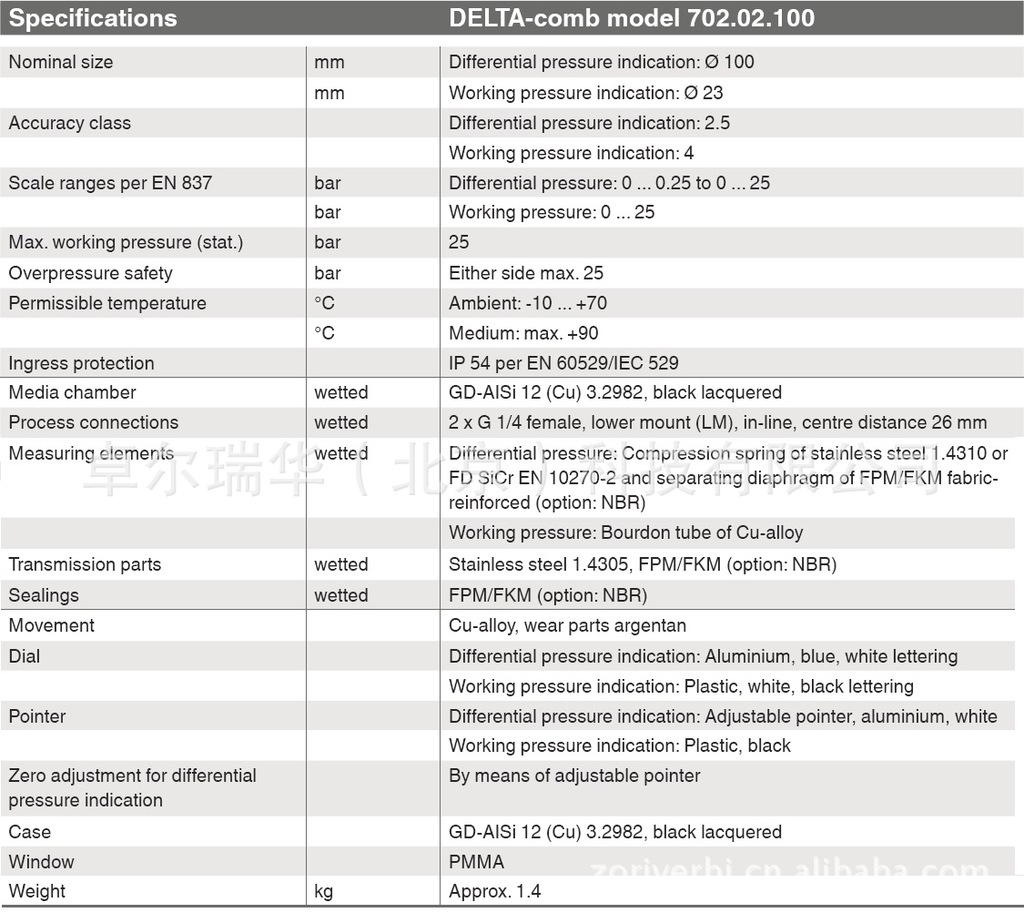

Integrated working pressure indication and micro switch Model 702.02.100

Applications

For gaseous and liquid media that are not highly viscous or crystallising

Heating, ventilation, air-conditioning, dust removing technology

Technical building equipment, filter systems, drinking and service water treatment

Monitoring and control of pumps in pressure boosting and fire-extinguishing systems

Special features

Differential pressure measuring ranges from 0 … 250 mbar to 0 ... 25 bar

High working pressure (static pressure) up to 25 bar

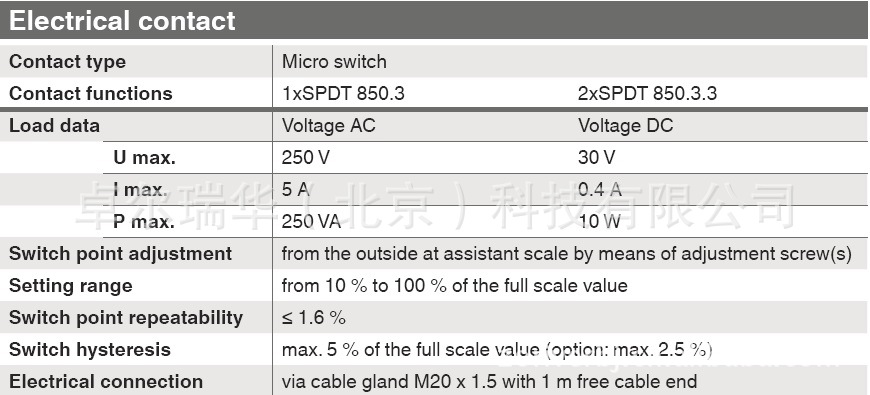

One or two adjustable micro switches

High repeatability of the switch points

Debion

These differential pressure gauges are particularly used for the monitoring and control of differential pressures in filter systems, pumps and pipeline systems in the heating, ventilation and air-conditioning sector, technical building equipment and in the water management industry.

Apart from the display of the differential pressure, these applications also require, as a rule, the display of the current working pressure. For this reason, a working pressure indication is integrated in the DELTA-comb differential pressure gauge as a standard.

An additional measuring point for the working pressure indication, involving additional expenses for piping and mounting, is thus no longer required. The white dial of theworking pressure indication distinctly stands out against the blue background of the display of the differential pressure indication, thus enabling a quick and reliable reading of both measurement beters.

The scale ranges of 0 ... 250 mbar to 0 ... 25 bar are available to meet the requirements of a wide variety of applications.

With its robust and compact design the differential pressure gauge can even be used under tough industrial ambient conditions.

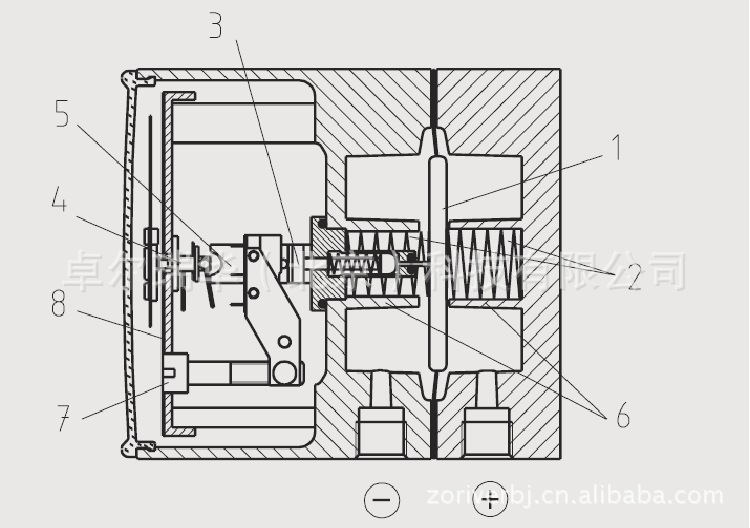

Design and operating principle

Pressures p1 and p2 act on the media chambers j and i, which are separated by an elastic diaphragm (1).

The differential pressure (Δp = p1 - p2) leads to an axial deflection (measuring travel) of the diaphragm against the measuring range spring (2).

The deflection, which is proportional to the differential pressure, is transmitted to the movement (4) in the indicating case and to the plungers of the micro switches (5) via a pressure-tight and low friction connecting rod (3).

Overpressure safety is provided by bl bolsters (6) resting against the elastic diaphragm.

The adjustment of the switch point is made by the adjustment screws accessible from the front (7). The assistant scales (8) enable a relatively accurate adjustment of the switch points over 270 p ° and indicate the set point that is currently

adjusted.

Illustration of the principle

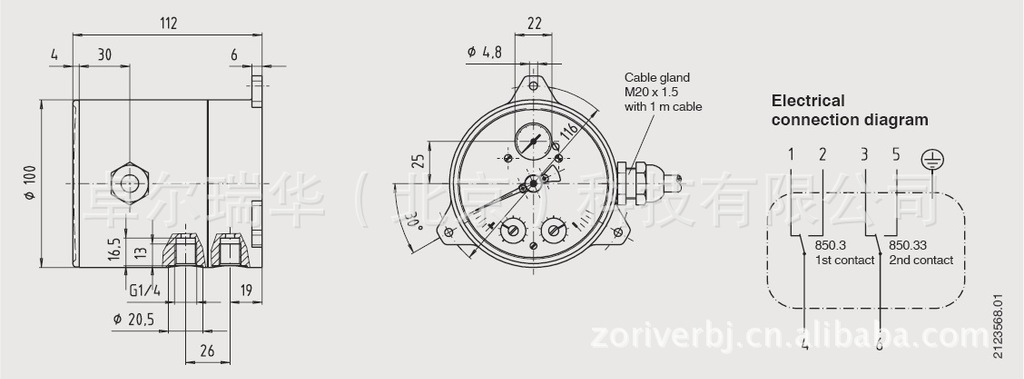

Mounting according to affixed symbols j and i,j high pressure, i low pressure

Mounting by means of:

rigid tailpipe or wall mounting with available mounting bs

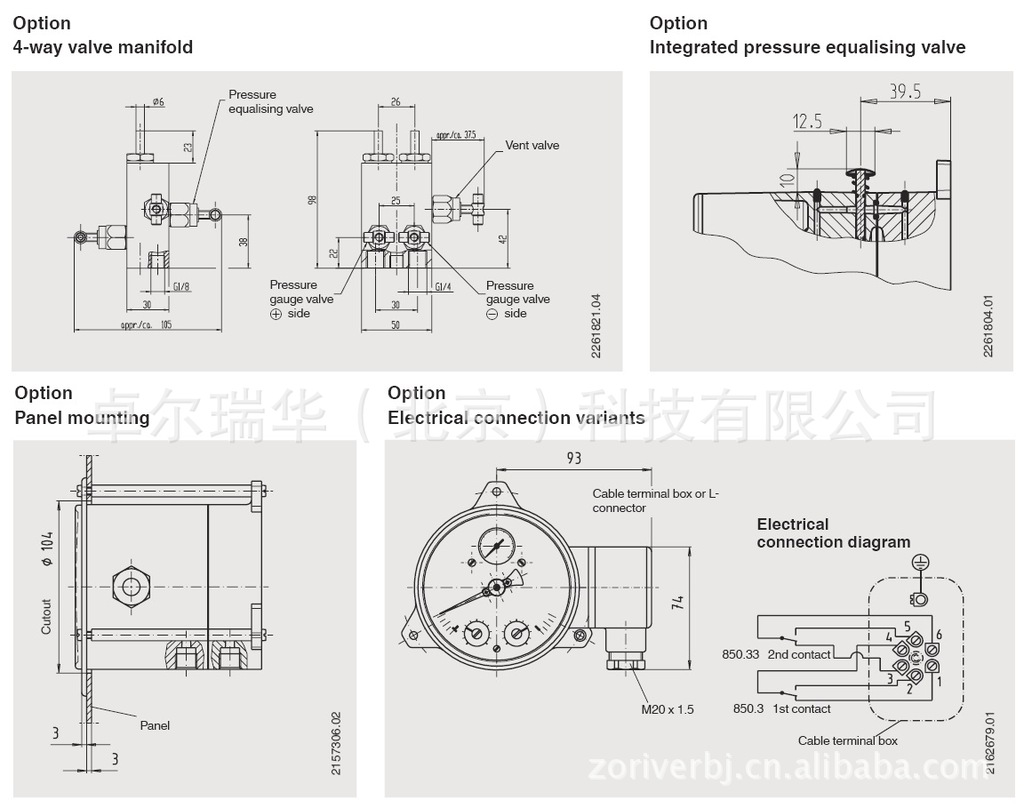

Options

Media chamber GD-AlSi 12 (Cu) HART-COAT-surface protection

Media chamber of stainless steel (without working pressure indication)

Accuracy class 1.6 for differential pressure indication with factory-set switch points for scale ranges from 0 ... 1 bar to 0 ... 25 bar (switching direction to be specified)

Ingress protection lP 65

Integrated pressure equalising valve(stainless steel and FPM/FKM)

4-way valve manifold of Cu-alloy or stainless steel,(1x pressure equalising valve, 2x pressure gauge valve,1x valve for purging and ventilating)

Other threaded process connections female and male

Compression fittings with ferrule or clamp ring for pipe diameters 6, 8 and 10 mm

Panel mounting flange

Electrical connection via cable terminal box M20 x 1.5 or L-connector

Dimensions in mm

Ordering inbation

Model / Scale range / Process connection / Material of media chamber / Material of separating diaphragm and sealings /Accuracy class for differential pressure indication / Options

欢迎致电咨询订购WIKA 702.02.100 DELTA-comb 差压表 带集成工作压力表和微型开关

电话:010-51669912 56291930 15910733293

传真:010-51669912

QQ:823377546 1491421115 2636968574

邮箱:sales@zoriver.cn

- LAM 679-158076-202 MKS VIP1004

- 西门子罗宾康A5E00338473 光纤通讯板行情

- 6ES7422-5EH10-0AB0新品上架

- A1A10000432.54M变频器单元控制板设备型号

- MKS Instruments VPR3A33CR1BH00

- A1A10000350.00M单元控制板性能介绍

- 西门子罗宾康A5E39021143 功率单元图片

- A1A10000432.71M控制板简介

- 库存现货 西门子 1FT6105-0SC71-4EB0

- 6ES7498-8AA05-8CA0新品热卖

- 罗宾康A5E36184868功率单元现货特价

- 库存现货 西门子 1FT6102-8AH71-4AG1

- 罗宾康LDZ31500082.315功率单元技术参数

- 库存现货 西门子 1FT6102-8AC71-4AB0

- A1A10000423.00M接口板特点