WIKA DPGT43HP 带过压保护全钢电接点差压压力表 适用于所有介质

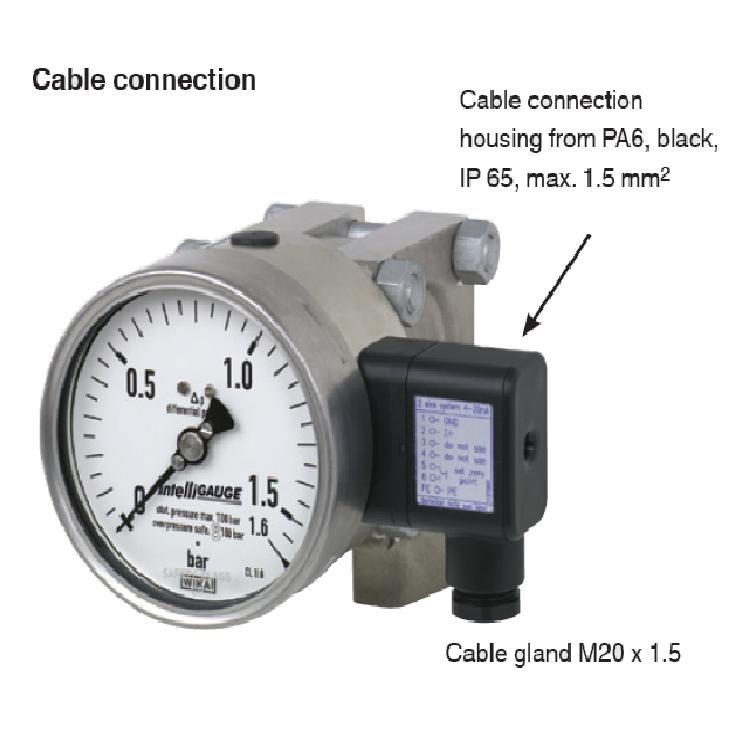

Differential pressure gauge with electrical output signal

Universal version, high overpressure safety

Models DPGT43HP.100 and DPGT43HP.160

Differential pressure gauge model DPGT43HP.100

Applications

Acquisition and display of process values

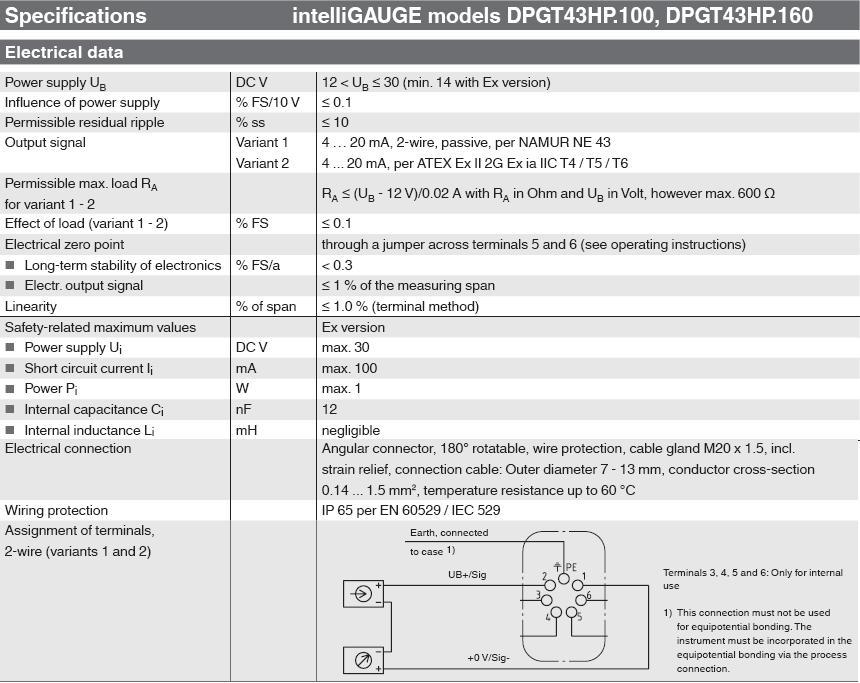

Transmission of process values to the control room (4 ... 20 mA)

For measuring bs with a high differential pressure overload and/or high working pressures (static pressures), also in aggressive ambience

Easy-to-read, analogue on-site display needing no external power

Special features

High working pressure (static pressure) and high overpressure safety, optionally up to 40, 100, 250 or 400 bar

Individual, non-linear characteristic curves (e. g. x2 or √x for flow measurement)

"Plug and play" with no configuration necessary

Differential pressure measuring ranges from 0 … 60 mbar

Hydraulic cushioning protection against rapid pressure changes

Debion

At any point where a differential pressure has to be indicated locally, and, at the same time, a signal is wanted to be transmitted to a central controller or remote control room, the model DPGT43HP inbliGAUGE (patent applied for, among

others European Patent No. EP 06113003) can be used.

The electronic WIKA transmitter, integrated into the model 732.14 high-quality mechanical differential pressure gauge, combines the advantages of electrical signal transmission with the advantages of a local mechanical display.

Even if the power supply is compleby lost, the differential pressure can be read securely. The rugged design of the diaphragm measuring system produces a pointer rotation proportional to the pressure.

An electronic angle encoder, proven in safety-critical automotive

applications, determines the b of the pointer shaft - it is a non-contact sensor and therefore compleby free from wear and friction. From this, the electrical output signalproportional to the pressure, 4 ... 20 mA, is produced. The

electrical zero point can also be set manually.

These differential pressure gauges are made of highly corrosion-resistant stainless steel. A high overpressure safety is achieved by the all-bl construction and the close-fitting design of the diaphragm measuring element.

With its high-grade stainless steel construction and robust design this pressure gauge is geared to chemical and process engineering applications. It is suitable for gaseous or liquid media, also in aggressive ambience.

The wetted parts for these differential pressure gauges are available also in special materials such as Monel, Hasbloy or PTFE.

Standard version

Design

highest overpressure safety either side, pressure ratings

PN 40, 100, 250 oder 400,

Hydraulic cushioning protection against rapid pressure changes

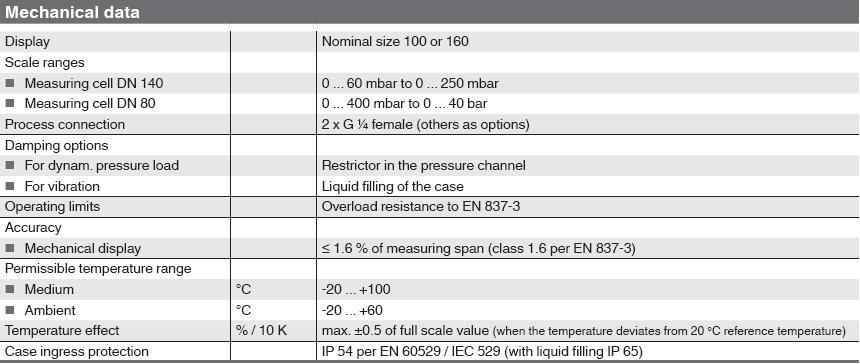

Nominal size in mm

100, 160

Accuracy class

1.6

Scale ranges

0 ... 60 mbar to 0 ... 250 mbar (measuring cell DN 140)

0 ... 0.4 bar to 0 ... 40 bar (measuring cell DN 80)

With overpressure safety 400 bar: 0 ... 0.4 bar to 0 ... 40 bar or all other equivalent vacuum or combined pressure and vacuum ranges

Pressure limitation

Steady: Full scale value

Fluctuating: 0.9 x full scale value

Overpressure safety and max. working pressure (static pressure)

either side max. 40, 100, 250 or 400 bar

Pressure elements (wetted)

Stainless steel / NiCrCo-alloy (Duratherm)

Sealings (wetted)

FPM / FKM

Process connections (wetted)

Stainless steel 1.4571, lower mount (LM) 2 x G ¼ female

Venting of the media chambers (wetted)

Stainless steel 1.4571 for scale ranges ≤ 0.25 bar (option for scale ranges ≥ 0.4 bar!)

Measuring cell

Chrome steel

Movement

Brass

Dial

Aluminium, white, black lettering

Pointer

Adjustable pointer, aluminium, black (with the liquid filling option: Standard pointer, aluminium, black)

Zero adjustment

By means of adjustable pointer

Case / Bayonet ring

Stainless steel, ingress protection IP 54

Window

Laminated safety glass

Measuring cell filling

Silicone oil

Mounting

according to affixed symbols

⊕ high pressure, ? low pressure

Mounting by means of

Rigid measuring lines

Mounting holes in measuring flange

Panel mounting flange (option)

Mounting bracket for wall or pipe mounting (option)

Options

Liquid filling (silicone M50)

Venting of the media chambers for scale ranges ≥ 0.4 bar Measuring cell filling with special medium, e.g. for use

oxygen applications (static pressure max. 100 bar)

Measuring cell filling with special medium, e.g. for use in

oxygen applications (static pressure max. 100 bar)

Customer-specific characteristic curve (also non-linear)

Combined display of differential pressure and working pressure

Wetted parts made of special material

Panel mounting flange

Mounting bracket for wall or pipe mounting, lacquered steel or stainless steel

Monel version

Version per ATEX Ex II 2G Ex ia IIC T4 / T5 / T6

Gost standard approval

Pressure equalising valve (data sheet AC 09.11)

Switch contacts (data sheet AC 08.01)

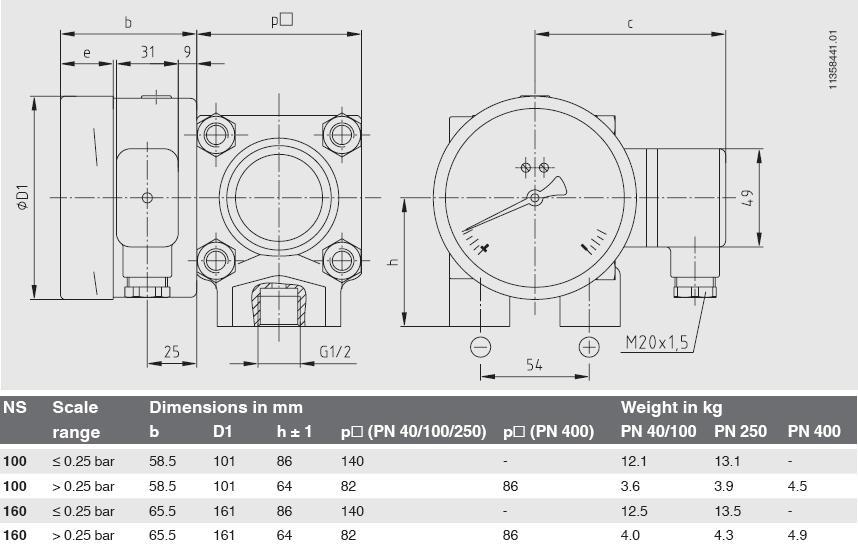

Dimensions in mm

Standard version

Ordering inbation

Model / Nominal size / Scale range / Connection size / Connection b / Output signal / Scale layout (linear pressure or

square root incrementation) / Max. working pressure (static pressure) / Options

CE conbity

EMC directive

2004/108/EC, EN 61326 emission (group 1, class B) and interference

immunity (industrial application)

ATEX directive

94/9/EC, II 2 G Ex ia IIC

欢迎致电咨询订购WIKA DPGT43HP 带过压保护全钢电接点差压压力表 适用于所有介质

电话:010-51669912 56291930 15910733293

传真:010-51669912

QQ:823377546 1491421115 2636968574

- 6ES7468-1DB00-0AA0质保一年

- A5E00297630触发板供应

- 罗宾康A5E37684782功率单元市场价格

- A5E36968571接口板特惠

- A1A10000423.00M功率单元正品低价

- A1A10000432.71M控制板优惠

- 6ES7405-0KA02-0AA0新品上架

- 罗宾康原装LDZ13500012.00特点

- A5E01649325输入输出板使用方法

- AX8575-12 with MkS AX8407HC

- 西门子罗宾康A5E03407403通信板说明书

- 33178 MKS ANGLE VALVE 100016885

- 罗宾康原装A1A10000423.00M说明书

- 调制板A1A10000350.00M特点

- 6ES7460--0AA01-0AB0新品上架