|

Model |

Outer dimensions and weight |

Hole beter |

||||||||||||||||||||||||||

|

The outer ring |

The inner ring |

|||||||||||||||||||||||||||

|

(In) oD |

(In) id |

H (In) |

(In) oH |

(In) iH |

(In) rD |

(In) rd |

G (Lbs) |

(In) oL |

on |

(In) oB |

(In) iL |

in |

(In) iB |

|||||||||||||||

|

16328001 |

26.700 |

18.667 |

2.500 |

2.000 |

2.000 |

— |

— |

130 |

24.500 |

18 |

1/2-13 |

20.500 |

18 |

1/2-13 |

||||||||||||||

|

16329001 |

36.000 |

24.160 |

3.880 |

3.380 |

3.380 |

— |

— |

465 |

33.250 |

24 |

0.813 |

27.250 |

30 |

3/4-10 |

||||||||||||||

|

16330001 |

41.500 |

30.320 |

4.190 |

3.370 |

4.000 |

— |

32.360 |

510 |

40.000 |

36 |

0.807 |

33.500 |

36 |

3/4-16 |

||||||||||||||

|

16331001 |

41.970 |

30.828 |

3.350 |

2.560 |

2.950 |

41.929 |

— |

400 |

39.961 |

24 |

M20x2.5 |

34.646 |

24 |

M20x2.5 |

||||||||||||||

|

16332001 |

54.740 |

44.400 |

4.500 |

3.750 |

4.130 |

— |

46.380 |

500 |

53.000 |

36 |

0.922 |

48.000 |

36 |

7/8-14 |

||||||||||||||

|

16333001 |

78.819 |

62.913 |

5.906 |

4.921 |

4.921 |

— |

65.157 |

2,050 |

76.575 |

48 |

1.181 |

67.520 |

48 |

1.181 |

||||||||||||||

|

16334001 |

114.000 |

95.000 |

6.000 |

5.500 |

5.500 |

— |

97.500 |

4,250 |

111.000 |

48 |

1.063 |

100.000 |

48 |

1-8 |

||||||||||||||

|

16335001 |

121.496 |

97.717 |

6.772 |

6.299 |

6.299 |

— |

— |

6,080 |

117.795 |

72 |

1.535 |

105.512 |

72 |

1.535 |

||||||||||||||

|

16336001 |

142.000 |

123.200 |

6.000 |

5.500 |

5.500 |

— |

— |

5,370 |

139.000 |

72 |

1.063 |

128.000 |

72 |

1.063 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

External tooth type

|

Model |

Outer dimensions and weight |

Hole beter |

||||||||||||||||||||||||||

|

The outer ring |

The inner ring |

|||||||||||||||||||||||||||

|

(In) oD |

(In) id |

H (In) |

(In) oH |

(In) iH |

(In) rD |

(In) rd |

G (Lbs) |

(In) oL |

on |

(In) oB |

(In) iL |

in |

(In) iB |

|||||||||||||||

|

16337001 |

16.000 |

9.190 |

2.170 |

1.770 |

1.850 |

14.880 |

9.250 |

55 |

14.094 |

24 |

0.562 |

10.197 |

24 |

0.562 |

||||||||||||||

|

16338001 |

23.333 |

13.750 |

2.750 |

2.500 |

2.500 |

— |

— |

175 |

20.875 |

12 |

0.688 |

15.375 |

12 |

0.688 |

||||||||||||||

|

16339001 |

27.362 |

18.780 |

3.030 |

2.520 |

2.240 |

26.380 |

18.900 |

180 |

25.197 |

18 |

0.688 |

20.000 |

18 |

0.688 |

||||||||||||||

|

16340001 |

33.627 |

26.535 |

2.205 |

1.752 |

1.752 |

— |

— |

140 |

30.906 |

36 |

M12x1.75 |

27.480 |

40 |

0.551 |

||||||||||||||

|

16341001 |

36.333 |

24.500 |

4.690 |

4.310 |

3.880 |

35.500 |

24.625 |

580 |

33.625 |

24 |

0.813 |

26.125 |

24 |

0.813 |

||||||||||||||

|

16342001 |

45.050 |

34.180 |

3.930 |

3.360 |

3.470 |

42.840 |

42.840 |

470 |

41.338 |

24 |

0.866 |

35.826 |

24 |

0.866 |

||||||||||||||

|

16343001 |

51.040 |

40.000 |

4.000 |

3.500 |

3.500 |

— |

— |

680 |

48.200 |

36 |

0.813 |

41.800 |

36 |

0.813 |

||||||||||||||

|

16344001 |

63.150 |

47.480 |

5.118 |

4.409 |

4.409 |

61.063 |

47.559 |

1,420 |

58.819 |

36 |

1.023 |

50.394 |

36 |

1.023 |

||||||||||||||

|

16345001 |

70.510 |

53.540 |

5.040 |

4.330 |

4.330 |

— |

— |

1,460 |

65.354 |

42 |

1.063 |

55.906 |

42 |

1.063 |

||||||||||||||

|

16346001 |

85.866 |

75.250 |

3.300 |

2.800 |

2.800 |

— |

— |

920 |

82.750 |

48 |

0.813 |

77.250 |

48 |

0.813 |

||||||||||||||

|

16347001 |

100.667 |

84.000 |

6.500 |

6.500 |

4.000 |

98.750 |

84.250 |

3,240 |

95.000 |

48 |

1-8 |

87.000 |

48 |

1.063 |

||||||||||||||

|

16348001 |

159.843 |

141.732 |

6.142 |

5.748 |

5.748 |

— |

— |

5,480 |

154.528 |

100 |

1.299 |

144.685 |

100 |

1.299 |

||||||||||||||

|

16393001 |

209.843 |

188.583 |

7.047 |

6.417 |

6.024 |

206.299 |

188.858 |

9,750 |

202.362 |

100 |

1.299 |

191.339 |

100 |

1.299 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

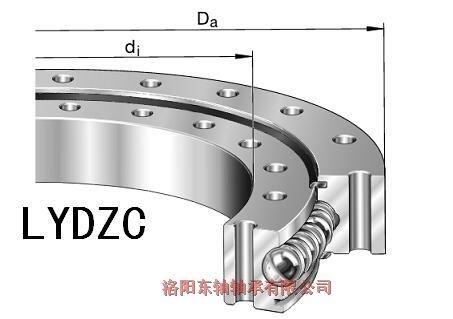

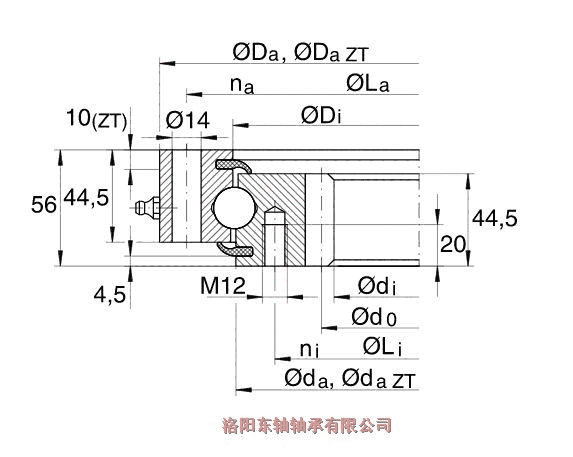

RK系列轴承一个或者两个套圈上有法兰,尺寸范围是外径20-47英寸(500-1200mm)。法兰设计降低了重量,并且使设备设计者能够更灵活的设计相邻安装结构的外形和螺栓的排布。当尺寸大重量轻作为选择轴承的主导因素时,RK系列适合多种应用。

设计特点

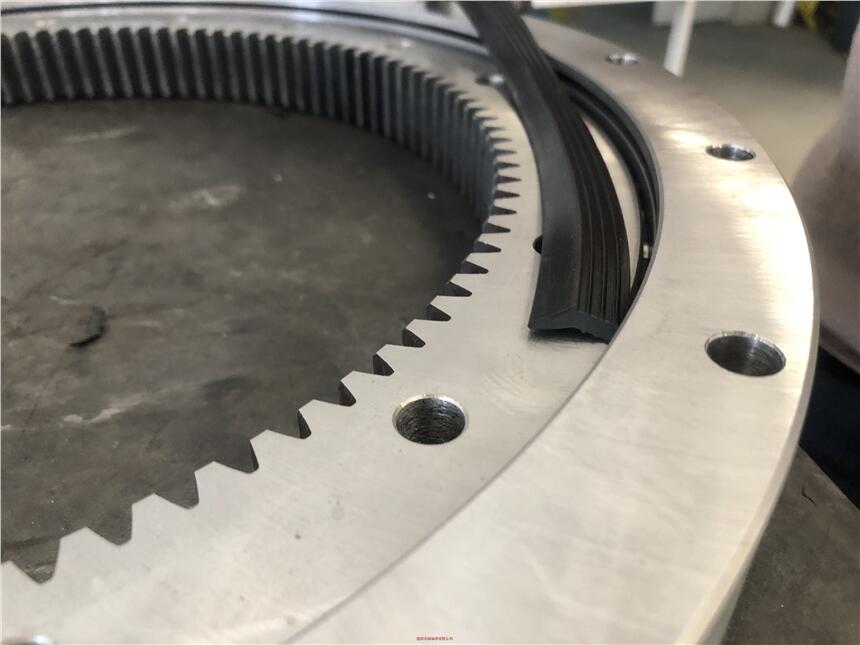

其内部结构是深沟滚道,通过滚珠达到四点接触,使轴承能够同时承担径向、轴向和力矩载荷。间隔球与承载球间隔布置,能够降低旋转阻力转矩,在进行摆动运动的场合可以得到更好的性能。完美的相向密封能够帮助排出污染物。RK系列轴承有无齿、内齿和外齿的形式,为设计者提供的选择灵活性。轴承采用渐开线短齿设计,压力角20度,能够达到AGMA Q5级精度,许可齿侧间隙为0.005至0.015英寸。所有的该类轴承都带有4个间隔90度的油嘴。无齿和内齿的轴承,油嘴位于外径阶梯处。外齿的轴承,油嘴位于内径阶梯处

表1 CRA系列的内圈旋转精度

Table 1 CRA series inner ring rotation accuracy

单位:um

|

轴承内径(d)的公称尺寸(mm) Bearing inner diameter (d) of the nominal size (mm) |

径向跳动 |

|

|

轴向跳动 |

||

|

超过 |

以下 |

公差 |

|

40 |

65 |

13 |

|

65 |

80 |

15 |

|

80 |

100 |

15 |

|

100 |

120 |

20 |

|

120 |

140 |

25 |

|

140 |

180 |

25 |

|

180 |

200 |

30 |

表2 CRB系列的内圈旋转精度

Table 2 CRB series inner ring rotation accuracy

单位:um

|

轴承内径(d的公称尺寸(mm) Bearing inner diameter of the nominal size |

内圈径向跳动公差 Radial runout tolerance of inner ring |

内圈轴向跳动公差 Axial runout tolerance of inner ring |

|||||||||

|

超过 |

以下 |

P0 |

P6 |

P5 |

P4 |

P2 |

P0 |

P6 |

P5 |

P4 |

P2 |

|

18 |

30 |

13 |

8 |

4 |

3 |

2.5 |

13 |

8 |

4 |

3 |

2.5 |

|

30 |

50 |

15 |

10 |

5 |

4 |

2.5 |

15 |

10 |

5 |

4 |

2.5 |

|

50 |

80 |

20 |

10 |

5 |

4 |

2.5 |

20 |

10 |

5 |

4 |

2.5 |

|

80 |

120 |

25 |

13 |

6 |

5 |

2.5 |

25 |

13 |

6 |

5 |

2.5 |

|

120 |

150 |

30 |

18 |

8 |

6 |

2.5 |

30 |

18 |

8 |

6 |

2.5 |

|

150 |

180 |

30 |

18 |

8 |

6 |

5 |

30 |

18 |

8 |

6 |

5 |

|

180 |

250 |

40 |

20 |

10 |

8 |

5 |

40 |

20 |

10 |

8 |

5 |

|

250 |

315 |

50 |

25 |

13 |

10 |

|

50 |

25 |

13 |

10 |

|

|

315 |

400 |

60 |

30 |

15 |

12 |

|

60 |

30 |

15 |

12 |

|

|

400 |

500 |

65 |

35 |

18 |

14 |

|

65 |

35 |

18 |

14 |

|

|

500 |

630 |

70 |

40 |

20 |

16 |

|

70 |

40 |

20 |

16 |

|

|

630 |

800 |

80 |

|

|

|

|

80 |

|

|

|

|

|

800 |

1000 |

90 |

|

|

|

|

90 |

|

|

|

|

|

1000 |

1250 |

100 |

|

|

|

|

100 |

|

|

|

|

盘轴承的代号表示法

本公司转盘轴承采用了JB/T2300-1999的表示方法:采用分别表示滚动体类别、滚道结构型式和齿轮啮合方式,滚动体直径,滚动体中心圆直径及材料与毛坯型式等内容的全数字式综合表示法:

示例:

|

|

|

|

|

|

|

|

|

套圈材料及毛坯供应状态的代号按表1、2的规定,表中“T”表示套圈毛坯为调质状态供应,“Z”表示套圈毛坯以正火状态供应。表1

|

代号 |

01 02 03 04 05 06 |

|

材料及毛坯状态 |

45BT 45BZ 42CrMoT 42CrMoZ 5CrMnMoT 5CrMnMoZ |

表2

|

代号 |

07 08 09 10 11 12 |

|

材料及毛坯状态 |

42SiMnT 42SiMnZ 45MnT 45MnZ 50MnT 50MnZ |

示例:

滚动体中心圆直径为2500mm,球径为60mm,齿轮模数m=18mm,套圈材料用50Mn,毛坯材料为正火状态制造的内齿式四点接触球转盘轴承表示为013·60·2500·12

转盘轴承的密封一方面是为了防止已充填的润滑脂向外泄漏,另一方面是为了防止外界的尘埃,杂质及水分侵入轴承内部而影响其正常工作。由于转盘轴承大多处于重载低速下工作,故轴承的密封型式采用橡胶密封和迷宫式密封两种结构。而橡胶密封圈式密封本身具有结构简单、占用空间小、密封性能可靠等优点而得到了广泛的应用,但其不足之处是在高温状态时橡胶密封唇易早期老化而丧失密封性,故在高温工况条件下工作的转盘轴承宜采用迷宫式密封。

- 全新 TEL 东京盘子,EXHAUST Y-AL(3D10-150520-11

- DS2143-000042-11 / TEL 加热器

- TEL Tokyo Electron 5087-404181-12

- TEL 东京电子板,CNTR EXT CHEM OYDK-095B

- WUG-022NK13D2URT1-WRST-026X58T1-WTM-02P-40

- 2187-387902-11 / BRANCH

- 1181-000253-1B / TEL-ALPHA

- 2187-347566-11 / 电缆组件..电机/东京电子

- TS3281-001020-13 / TEL 板

- TEL Tokyo Electron 1810-121190-A2

- TEL Tokyo Electron 1810-329582-11

- 东京电子(TEL)281-500431-2 PCB

- 东京电子 TEL 清洁跟踪控制器 UC-105

- TEL Tokyo Electron 3281-000032-12 PCB

- TEL Tokyo Electron D3.0 P35.6 W-LB