- 产品介绍

产品简介

| 其他品牌 | 价格区间面议 |

| 微流控芯片系统 | 应用领域电子 |

| PlasmaEtch |

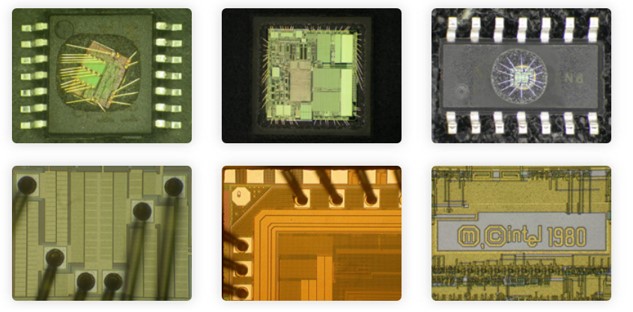

当今世界越来越关注生态友好,半导体生产工艺的持续改进则进一步导致了集成电路内部组件尺寸越来越小,也变得越来越灵敏和脆弱。由此导致了芯片失效分析的一个特定挑战:如何将样品封装去除却不会导致功能失效? Nisene公司x一代的芯片开封系统为半导体生产制造技术和失效分析之间的鸿沟搭建了一座桥梁:等离子芯片开封机—PlasmaEtch Nisene科技集团有限公司从事集成电路失效分析的自动开封装置研发超

详细介绍

当今世界越来越关注生态友好,半导体生产工艺的持续改进则进一步导致了集成电路内部组件尺寸越来越小,也变得越来越灵敏和脆弱。由此导致了芯片失效分析的一个特定挑战:如何将样品封装去除却不会导致功能失效? Nisene公司xin一代的芯片开封系统为半导体生产制造技术和失效分析之间的鸿沟搭建了一座桥梁:等离子芯片开封机—PlasmaEtch Nisene科技集团有限公司从事集成电路失效分析的自动开封装置研发超过40年,拥有多项电化学及微波等离子开封机技术的专li。

PlasmaEtch Process - 美国专li9,548,227 B2 - 使用等离子体放电管的微波诱导等离子体。

微波诱导式等离子芯片开封系统 ---- PlasmaEtch

无论是传统的金线样品,还是样品都采用铜线或银线,PlasmaEtch都能提供安全可靠的蚀刻。

As the world moves toward more eco-friendly processes and the semiconductor manufacturing industry continues to make smaller parts with sensitive internal components, failure analysts are presented with a unique challenge: how do you etch these samples? Nisene Technology Group has bridged the gap between semiconductor manufacturing technology and failure analysis with its latest decapsulation system: the PlasmaEtch.

工作原理:

The PlasmaEtch decapsulation system is a revolutionary patent-pending gas-based semiconductor etching system. Employing a never-before-seen application of microwaved gases inciting chemical radicals for isotropic etching, the PlasmaEtch is the greenest and most cost-effective etching solution available. The PlasmaEtch can etch most sample sizes, encapsulant types, and wire bond types. Whether it’s a more traditional gold wire sample, or if the sample features copper or silver wires, the PlasmaEtch delivers a safe and reliable etch.

PlasmaEtch创新点:

Afterburner Downstream Focused Plasma Etching(延时激发下行聚焦离子蚀刻)

Mass Flow Controlling for All Gases(所有气体流量可控)

No Microwave Radiation Exposure to Samples During Etch Process(无微波辐射)

Low Temperature Etching(低温蚀刻)

Isotropic Etching(等向性蚀刻)

Unlike typical and less sophisticated plasma decap systems that take many hours or even days to get to the surface of the die, the PlasmaEtch can b the encapsulant of most package types and reveal the complete die surface and wire sweep in a matter of a couple hours. Chemical-free decapsulation has never been so effective.

主要特色(Highlights):

Highly Customizable Etch Recipes(高度可定制的蚀刻配方)

Etches a Wide Variety of Package Types(可蚀刻各种各样的封装类型)

Compleby Chemical-free Decap(完全非化学方式蚀刻)

Eco-friendly(生态友好环保)

Touchscreen Interface(触控屏)

PC/Windows-based GUI(基于PC / Windows的GUI)

The Only Solution for Silver Wires(银线的唯1解决方案)

Etches Samples with All Wire Types(可蚀刻所有引线类型的样品)

Small Footprint Suited for Tabletop(桌上型紧凑尺寸机柜)

- 变频器 驱动器IC200UEX010耐用性强

- 变频器 冗余模块IC200UEO108为您做得到

- 变频器 驱动器IC200UAL004结构紧凑

- 接触器 模块IC200UAL005安全性能高

- 控制器 端子IC200MDL730顺丰速运

- 电源模块 伺服驱动IC200TBX340诚信经营

- 电源 机架IC200CBL520我必承诺

- 电源 机架IC200GBI001调试方便

- 控制器模块 plcIC200UEX636我们一直在努力

- 接触器 控制器IC200ALG261容量充足

- 驱动器 电缆IC200ALG240为你所委托

- 传感器 伺服驱动IC200MDL143我们一直在努力

- 变频器 驱动器IC200MDL240安全环保

- 输出模块 通讯模块IC200UEX824进口配件

- 变频器 驱动器IC200MDL144让我们做得更好